R&D Capabilities

20 years’ know-how and R&D experience in injection plastic magnet parts

World class capability to assist customers on tailor-made injection bonded magnet

New product development and technical standard formulation;

Mold and tooling development and design; Production automation planning and design.

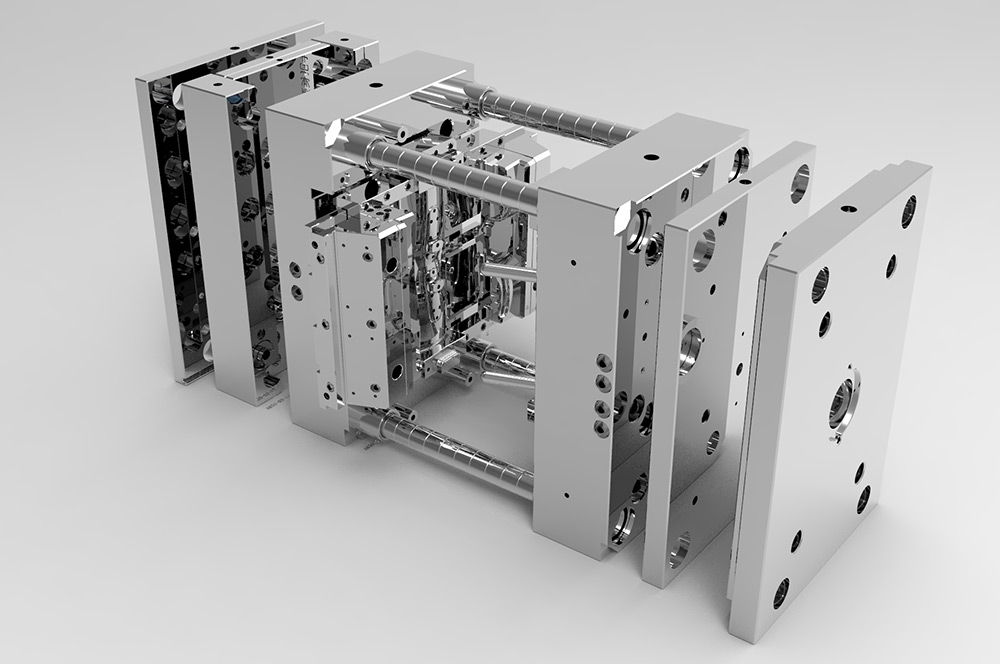

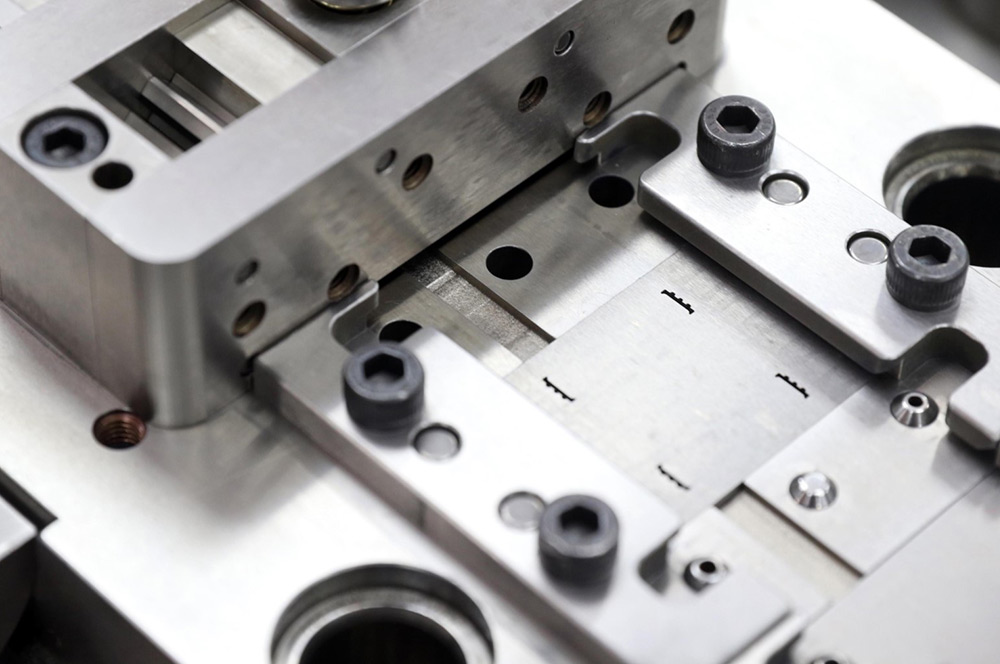

Mold Processing Capability

Precise Processing Tool & Facility for Molding Workshop:

---Mirror EDM

--- Wire-electrode Cutting Machines

--- Internal & External Cylindrical Machine

Monthly Processing Capacity:

--- 10 Sets Of Serial Tooling

--- 6 Sets Of Automatic Facility Or Fixture

--- Independent mold development department, can highly control the accuracy of products; Tooling parts development and processing assembly; Automatic parts development and processing

Molding Cavity Parts & Magnetizing Fixture

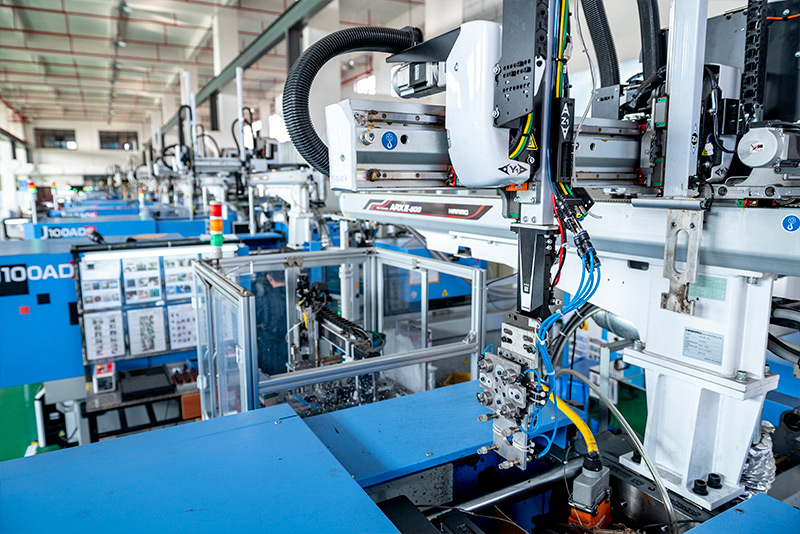

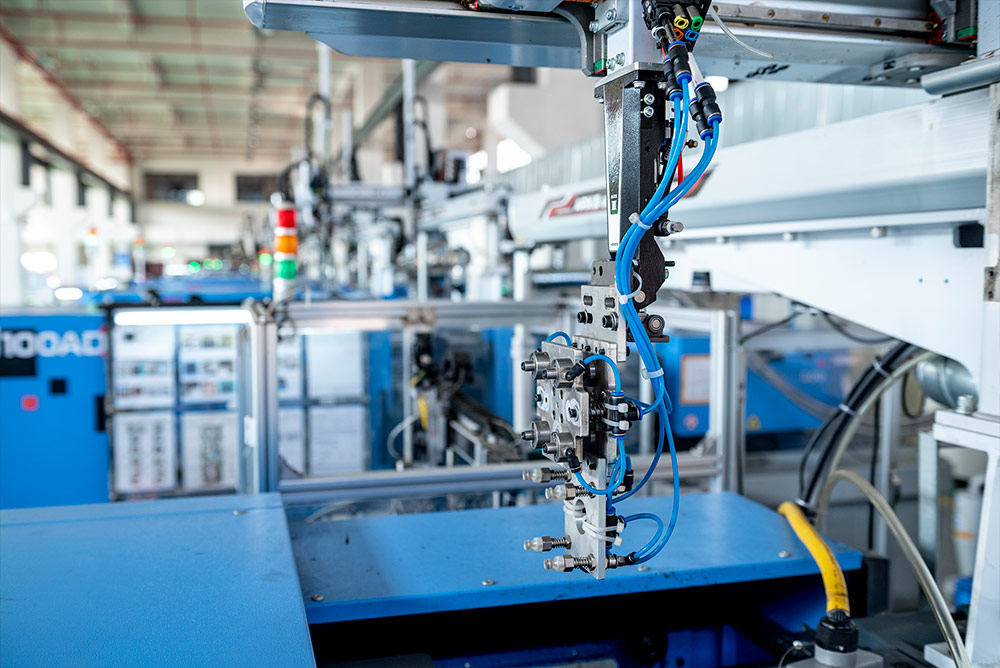

Manufacturing Capability

Automatic Injection Machine: 40 sets (Consume 900 tons/month of material)

Engineering Dept

Injection parameter development and standard formulation, automatic process research and execution

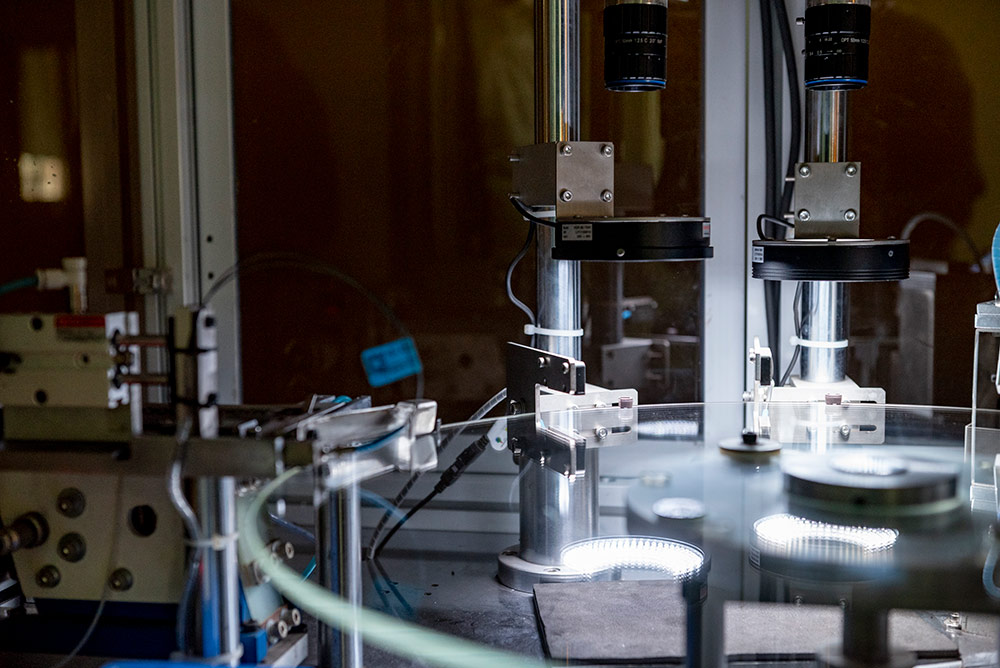

Appearance Optical Inspection Automation

Automatic Production

Automatic Production

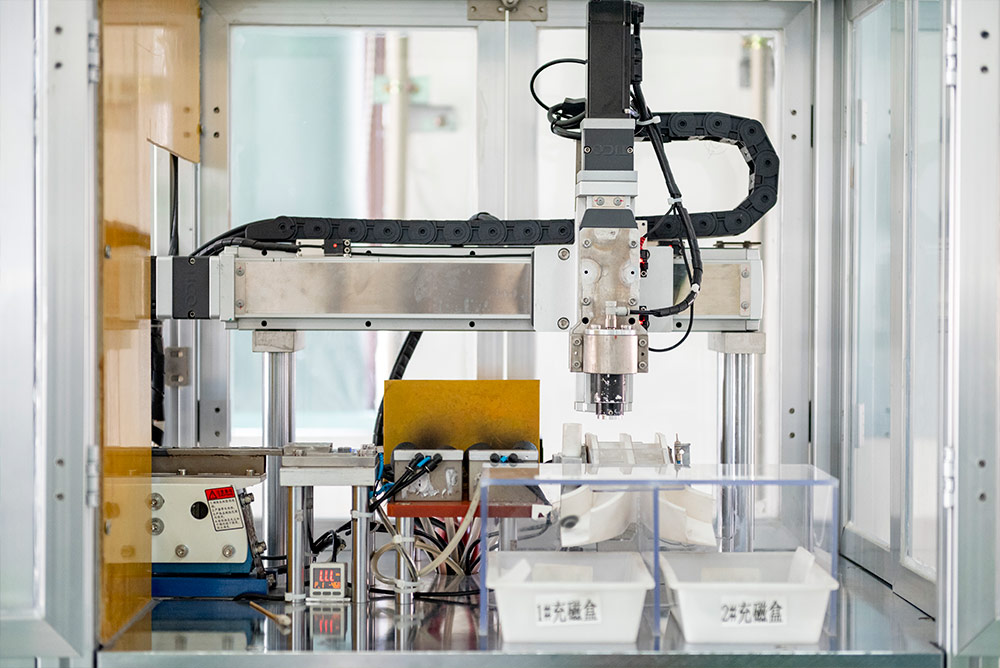

Magnetization Automation

© Copyright Jiangmen Maxwell Magnet Industry Co., Ltd All Rights Reserved. ICP:No.12084992 Design: EPD